3.1 Introduction

The project work is a delicate one

to design in board as lots of Fragile device needs to be soldered and fixed to

make it operational, But initial presumption is made totally on the modeling

aspect of the project in terms of components to be used in our research work,

The paragraph below will give an idea about the various components deployed in

our project work.

3.2 Components Deployed

The various components deployed for

the development of the model are provided in the following list.

Components

|

Quantity

|

Cost per component

|

Total cost

|

TLP RLP

pair (Transmitter and Receiver)

|

1

|

600

|

600

|

AT89c2051

|

1

|

70

|

70

|

AT89c51 IC

|

1

|

70

|

70

|

HT12E IC

|

1

|

50

|

50

|

HT12D IC

|

1

|

50

|

50

|

MAX232 IC

|

1

|

25

|

25

|

DB9 Connector

|

1

|

10

|

10

|

11.0592Mhz crystal

|

1

|

12

|

12

|

ULN2003 IC

|

2

|

10

|

20

|

Relays

|

8

|

25

|

200

|

Stepper Motor

|

2

|

250

|

500

|

Switch mode power supply

|

1

|

500

|

500

|

Discreet Register

|

15

|

1

|

15

|

Web Camera

|

1

|

700

|

700

|

Laser Pointer

|

4

|

20

|

80

|

Discreet Capacitors

|

10

|

8

|

80

|

Total

|

2982

|

Table

3.1: List of Component

Above table shows the list of

components with their cost and quantity which are deployed in the project

unmanned gun control mechanism, In this project we use AT89c51 microcontroller

which contains Non-volatile FLASH program memory that is parallel programmable.

PCB’s

|

Quantity

|

Design charges

|

Film making charge

|

PCB making charge

|

40 pin µc PCB

|

1

|

900

|

250

|

50

|

Relay PCB

|

2

|

650

|

150

|

20

|

20 pin µc PCB

|

1

|

700

|

150

|

30

|

Total

|

550

|

100

|

Table

3.2:

PCB Design & layout list

3.3 Block Diagram

Fig 3.3 (a):- Block diagram of receiver.

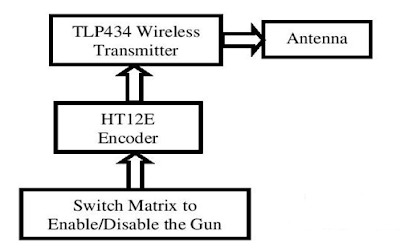

Fig

3.3(b): Remote

control to Disable/Enable the gun

Above

figure shows the block diagram of unmanned gun control mechanism. In this

project :-

v A

mechanism which will employ image processing in which a camera (Webcam) will be

continuously observing the "area under surveillance".

v This

data will be then processed by a MATLAB code which will be running on a pc and

will be able to detect a particular color (say Red) in front of a white

background (depicting snow).

v Depending

on this processed data the information about the intruder location will be sent

to a microcontroller (8051) via the serial/parallel port of the pc and then a

motor controlled gun will be used to point in the direction of the intruder.

v The

mechanism will be online i.e the Gun will continuously be pointing in the

direction of the intruder, further depending on range (Distance from the Gun)

the Gun can be activated and a laser pointer will be switched ON to depict

"Shooting the target".

v Another

feature of remote controlling will be incorporated to disable the device from a

distance lest .it might start shooting the people from the same country.

v For

this we will be using a wireless control employing TLP/RLP 434 devices whose wireless range can be extended up to 250Fts.

further to take care of certain condition when the enemy also visits the post

in white dress and the device might fail to detect him .we propose a laser

sensors deployment along the periphery which will be able to identify. In case

any thing has been present in front of it for a certain amount of time.

3.4 Circuit Diagram

3.4.1 Circuit diagram of Gun Pointer Transmitter

Figure 3.4.1: Circuit diagram of

Gun Pointer Transmitter

Above block diagram shows the Transmitter of the

gun pointer which are used for the purpose of enable & disable the gun.

Transmitter are connected with the HT12E encoder which takes the image from

webcam and segmented into 16 quadrants. Transmitter are driven by 5v dc

voltage.

3.4.2 Circuit Diagram Gun Pointer Receiver

Figure

3.4.2: Circuit Diagram of Gun Pointer Receiver

Circuit diagram of receiver is used MAX232

IC and DB9 connector which convert the input into serial port. HT12D decoder

are used by the receiver for modulate the ASK signal which are received from

the TLP transmitter. RLP is driven by the 5v dc voltage.

3.4.3 Circuit Diagram of Stepper Motor

Figure

3.4.3: Circuit Diagram of Stepper Motor.

Circuit

diagram of stepper motor is shown in the fig 3.4.3. In the above diagram

Stepper motor is directly connected to the Pin 13,14,15 and 16 of ULN2003.

Which is monolithic high voltage and high current Darlington transistor arrays.

It consist of seven NPN Darlington pairs that features high voltage outputs

with common cathode clamp diode for switching inductive loads. The motor has

full torque at standstill (if winding are energize).

3.4.4 Design of the system

The

design is mainly related to robot type

,the transmitter which we are using in this circuit is HT12E (encoder),which is

18 pin IC ,which works on +/- 12V,the address lines (AD0-AD3) connected in

series with the microcontroller (P3.3-P3.6) respectively, which intern

connected to switches and 17th pin of HT12E is connected in series with the

transmitter line pulse (TLP), its function is to send the ASK modulated signals

to the receiver (RLP).

ASK modulated signals from TLP is received from

the RLP and its digital output is sent to the HT12D, which is 18 pin IC, which

works at +/- 12V, the address lines

(D0-D3) is connected in series to the micro controller (P3.3-P3.6) which

intern connected to high voltage and high current darling ton transistor array

ULN, from pins(P0.0-P0.7) its function is to drive the relay from 5V to

12V,which is connected to the stepper motor.

The

microcontroller controls the stepper motor rotation and laser pointer direction

depending upon the serial data from the PC, here MAX232 IC is been used for the

TTL logic level compatibility.

No comments:

Post a Comment